At Curves, we believe that exercise can be continued for a long time only with a high degree of safety, which then can provide the health benefits of exercise. For that reason, we have been making various efforts with the aim of being No. 1 in safety and security.

Academic research results demonstrating high safety and low accident rate

We shared all accident history and safety management systems in Curves with the third-party research institute "Aichi Health Forest Health Science Center", and conducted joint research to improve safety. As a result, Curves was identified to have an exceptionally low accident rate as an exercise facility for middle-aged and elderly people. (Haruka Naito, Eri Nomura, Kazuyo Tsushita 2019), “Accident Occurrence Status and Safety Management System at National Chain Private Exercise Facilities -From Accident Report Surveys at 1,860 Curves Facilities -“, Japanese Journal of Clinical Sports Medicine, Vol. 27 258-265)

We are also implementing measures to further improve safety based on the results of this survey.

High safety of Curves exercise program

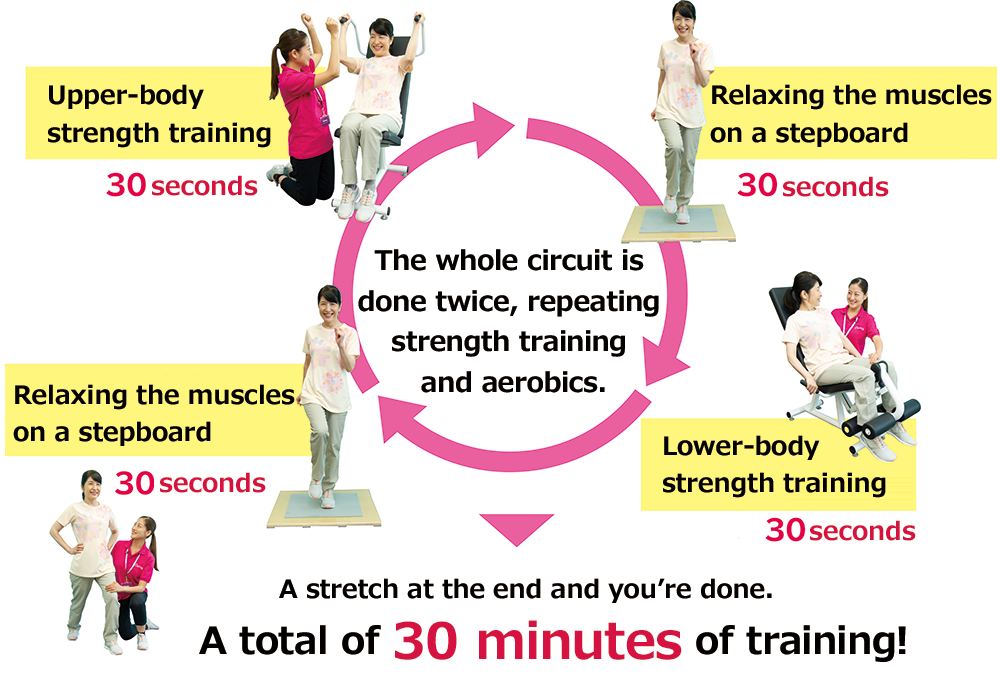

Curves uses a highly safe hydraulic machine and has a highly safe exercise program that measures your heart rate every 8 minutes during exercise. In addition, other measures are taken for safe club operations including AEDs equipped in all clubs.

Please see the link below for details.

https://www.curves.co.jp/medical/

*Website in Japanese

Safety management and PDCA cycle in clubs

Curves has established "National Curves Safety Week" once a year to reaffirm the safety of clubs and conduct training across the nation for achieving "the safer and more secure exercise facility". We reaffirm necessary measures for preventing equipment accidents, infection prevention, emergency and disaster response by putting up posters, conducting safety and disaster prevention inspections, creating disaster prevention maps, and confirming evacuation routes. We keep striving for continuous improvement in safety and security through the PDCA cycle.

Efforts for the security of information

For the Curves Group, information is our important asset, wherefore implementing appropriate information security measures is essential to maintaining our group's superiority and protecting customers’ personal information. Because of its importance, we have established internal regulations based on our information security policy and strive to manage and protect the information assets. In addition to building the management system to manage material information according to the level of confidentiality, we are working to ensure that employees are thoroughly familiar with education and regulations through conducting training on the handling of information assets as needed.

Curves’ Protein / Healthy Beauty

Initiatives for Safety and Reliability for customers

In order to deliver products that Curves members can consume with peace of mind, we implement rigorous quality control at factories that have obtained the GMP certification in the United States(※), which is recognized as the world's highest safety standard.

(※)GMP approved by NSF International, the certification body for nutritional supplements in the United States. Higher management standards than domestic GMP are required.

【Safe and reliable ingredients are carefully selected.】

After sourcing actual ingredients and conducting various analyses, only ingredients that meet Curves' quality standards are used.

〈Curves’ quality standards (partial)〉

- ①Commonly consumed as food. (e.g.: whey protein derived from milk, etc.)

- ② The origin is clear.

- ③ Processing plants have a high level of hygiene management and a proven track record of delivering to Japan.

- ④ No variation in ingredient content, taste or color.

- ⑤ Safety tests have proven that there are no problems.

(e.g.: acute toxicity, chronic toxicity, carcinogenicity, genotoxicity, etc.) - ⑥ Every batch of ingredients manufactured undergoes quality control tests.

(e.g.: whether no bacteria or metals are mixed in, etc.)

【Uncompromising quality control】

Change into clean work clothes and blow off even the smallest dust with an air shower.

▼

The manager checks whether the product is manufactured according to the correct procedures.

▼

Final products are checked with an X-ray detector to see whether no foreign objects are mixed in.

【Reliable support system】

In addition to support from our club instructors, we have established a dedicated call center for Protein Healthy Beauty to handle more specialized questions such as those about ingredients and drug interactions, and have a training system in place to ensure accurate and courteous responses.